R&D

In agreement with its charter, ICAS profit is re-invested for the development of high technology devices, mainly for power applications of superconductors.

The main Research & Development activities here summarized are performed by the ENEA SC team in close collaboration with the 2 industrial ICAS partners, TRATOS and CRIOTEC, in order to develop products which can be as close-to-market as possible.

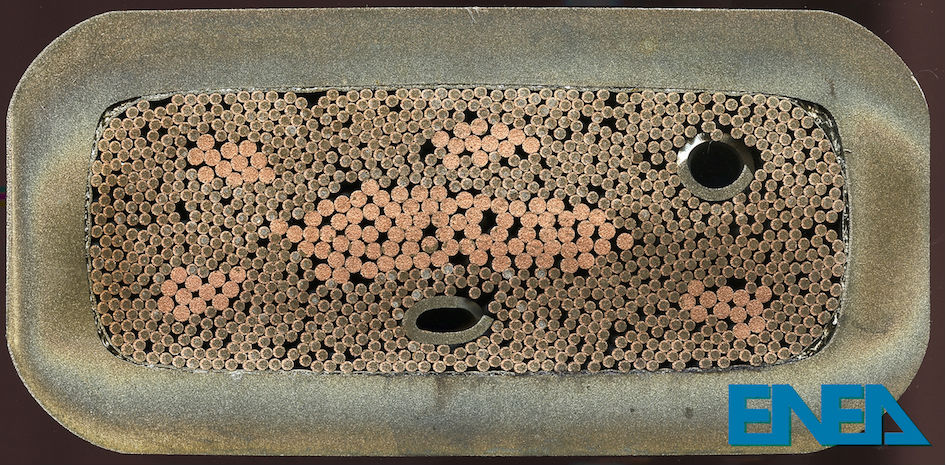

ENEA rectangular Conductor for DEMO fusion power plant

Within the frame of the design activities for the TF coil of the European DEMO nuclear fusion reactor, the 3 charter members of ICAS (ENEA, TRATOS and CRIOTEC) have designed and manufactured a rectangular Nb3Sn Cable-in-Conduit Conductor (CICC) with distributed pressure relief channels, that has reached the record performances of 81.7 kA in a magnetic field of 13 T up to about 7 K. The CICC test has been performed at the EDIPO facility, at the Swiss Plasma Center (Switzerland), that also collaborated to the manufacture of the sample, to its heat treatment, and to the installation of the instrumentation.

As already shown in the past by ENEA, the rectangular CICC geometry, together with a long twist pitch cable configuration and a low void fraction, allows to distribute the electromagnetic loads in such a way that no performance degradation with electromagnetic loading cycles, typical of CICC, is observed.

For further details see ENEA website.

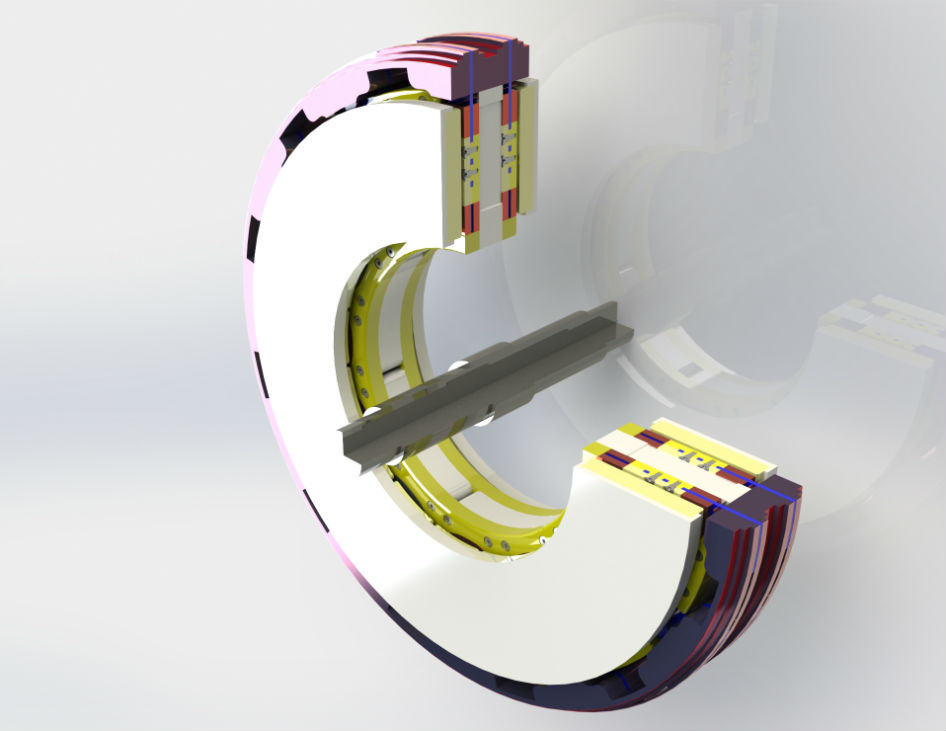

Axial Flux Superconducting Electrical Machine

ICAS is currently involved in the industrialization of an axial flux, permanent magnets, superconducting, 3-phases, ironless, synchronous generator, based on the original design developed by the ENEA SC team.

The first prototype will generate a power of 25kW, whereas in a second step it is foreseen to upgrade its value of 10 times at least (i.e. > 250 kW).

The goal is to demonstrate the market readiness of a MW-size SC generator during year 2017.

The main advantages of this HTS generator (also usable with minor modifications as an electric engine) are:

- a power density 10 times larger than the conventional ones

- its high efficiency (>99%) costant even at low rpm values (< 100rpm)

HTS Cables for Power Transmission/Distribution

ICAS is developing and testing different cables solutions aimed at transmitting large power values (> 300MVA) and at distributing medium power values (< 100MVA).

Some cable designs have been selected and are currently under investigations, in order to define the best layout for the 2 different applications.

The main characteristics driving this study are:

- reliability of the solution

- adaptibility of the manufacturing processes to the industrial actual capabilities

- ease of operation

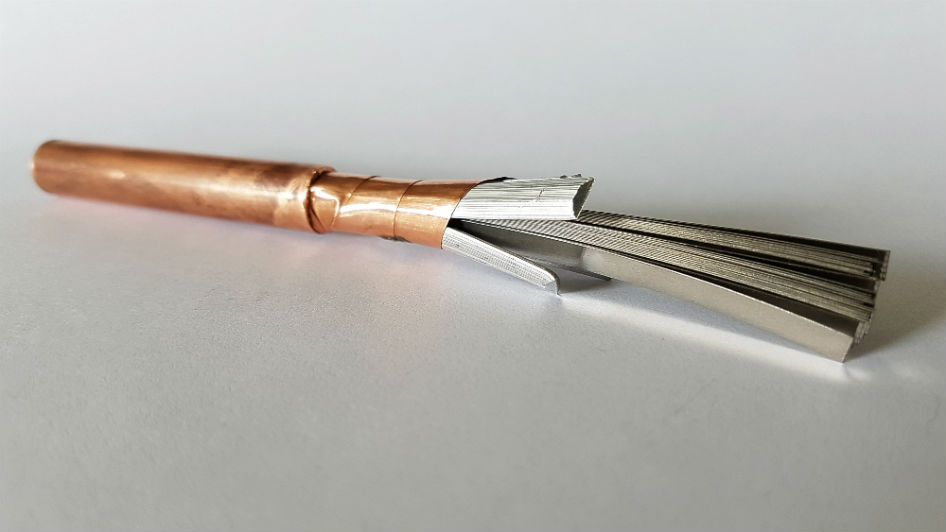

HTS Cables for High Field Magnets

A natural application of the HTS materials is in the High Field magnets, because of their relatively low field dependence in particular when working at low temperatures.

Due to the long experience of the ENEA SC team in the design of Nuclear Fusion magnets, a Cable-In-Conduit Conductor layout (typical technology of the Fusion magnets) for REBCO tapes has been designed, manufactured and successfully tested.

Further tests are on-going in order to fully define its performances in relevant operative conditions, in particular of a longer length conductor (> 30m) wound in a solenoidal shape which represents better the possibile real magnet.

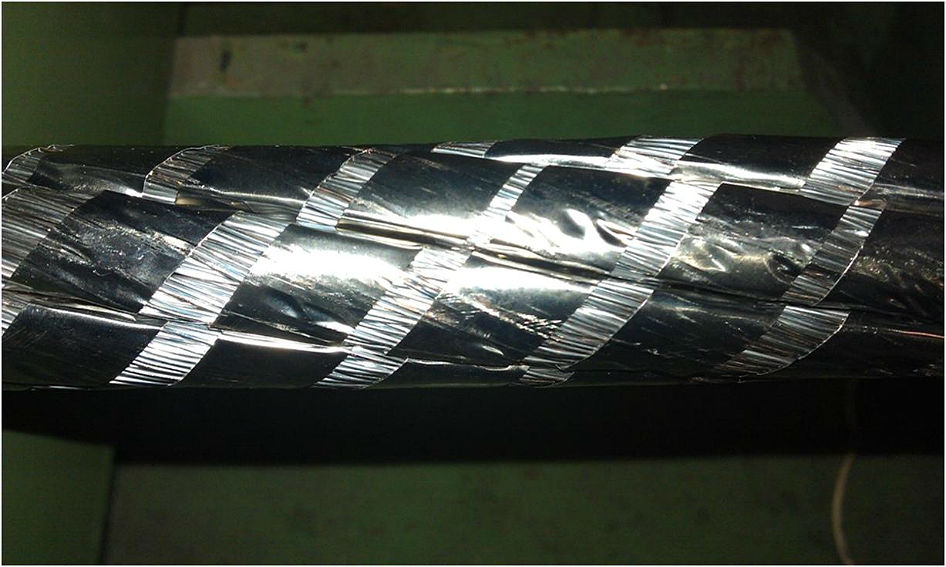

ITER Central Solenoid Cable Samples

The ITER Central Solenoid (CS) conductor full-size samples that qualified the final design have been manufactured between July and August 2011 by TRATOS Cavi (for cabling) and CRIOTEC Impianti (for jacketing). The four conductors were characterized by different cable / conductor layouts, and by the use of the best performing TF strands, including wires with a Cu:nonCu ratio of 1.5. The short vs. long twist pitch cable layout, with respect to the reference ITER CS cable layout, has been demonstrated and, based on the successful experimental campaign of such samples in the SULTAN facility (at SPC laboratories, Switzerland) ITER has been able to establish the final strand/cable design for the CS CICC.

CSIO1-Leg2: reference cable pattern

CSIO2-Leg2: short twist pitches cable configuration

CSIO2-Leg1: long twist pitches cable configuration