The Company

ICAS S.r.l. (Innovation and Consulting on Applied Superconductivity, Società a Responsabilità Limitata), is a private company originally setup in 2010 as a Consortium, in order to carry out the big duty of producing superconducting conductors

for the ITER and the JT-60SA tokamak experimental reactors.

In the following years ICAS was awarded supply contracts from all over the world and the range of production activities grew up consequently.

Currently, ICAS recognized excellence is not limited to superconducting Cable-In-Conduit conductors manufacturing, but covers also other and diversified high technology productions and services.

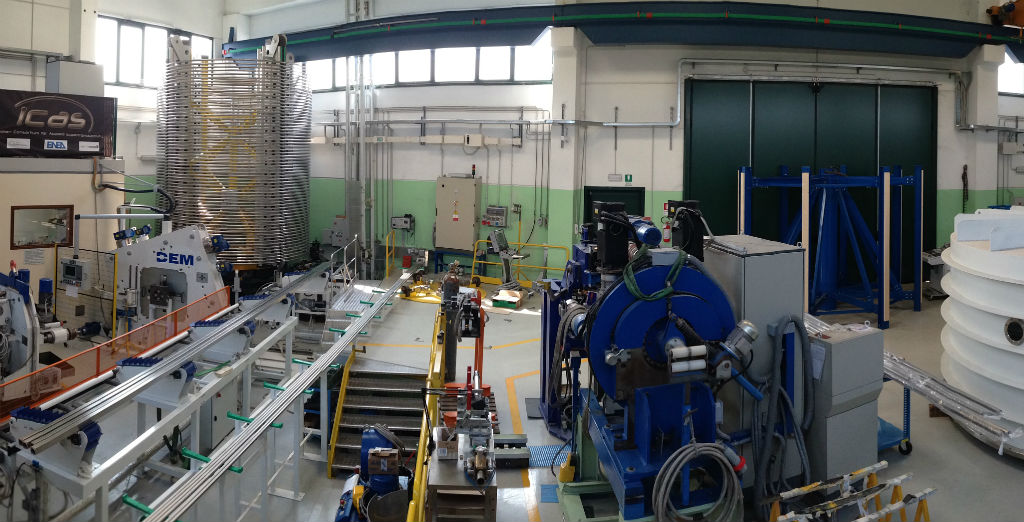

The Headquarters of ICAS are located inside the ENEA Frascati Research Center.

Here the main administrative and organizational processes, as well as laboratory tests are carried out.

In the TRATOS Cavi S.p.A. factory site of Pieve Santo Stefano (AR - Italy), ICAS performs all cabling activities plus other dedicated projects.

- One is dedicated to the manufacturing of Low Temperature superconducting cables (based mainly on Nb3Sn and NbTi strands) and it is been mainly used for the ITER and the JT-60SA productions.

- A second one is dedicated to the production of High Temperature superconducting cables, based mainly on YBCO tapes twisted into Aluminum slotted core: these cables are currently being used for the development of power distribution/transmission lines and for high-field magnets application.

- A third cabling line is currently devoted to the manufacturing of the complex cables for the Superconducting links of the Hi-Lumi project at CERN, based on MgB2 wires.

- Another line has been setup in order to apply a very thin insulating coating to favor the adhesion of resin during impregnation processes. Additionally, TRATOS is equipped with several extrusion lines for cable insulation.

- The newest line is currently devoted to the Non-Destructive tests (Eddy current + Ultrasonic) of long and thick copper tubes, to be used for the manufacturing of the mineral insulated conductors for the In-Vessel Coils of ITER.

A small-to-medium size coil winding line, complete of de-spooler, sand blaster, washing machine, wrapping machine and active winder, ovens for heat treatment and chambers for VP impregnation is available as well for a complete magnet production.

In the CRIOTEC Impianti S.r.l. factory site of Chivasso (TO - Italy), ICAS performs all conductors jacketing and magnet winding activities.

- 4 parallel 1000m long straight lines, adopted mainly for the TF and PF1/6 conductors of ITER;

- 6 x 300m long straight lines, adopted mainly for the TF conductors of JT-60SA;

- 4 x 150m (insulated) straight jacketing lines, currently used for the In-Vessel Coils of ITER.

All the jacketing lines are equipped with welding stations for round or square tubes, round-to-round and round-to-rectangular compaction machines, complete sets of NDE devices for weld checks

(X-rays, He leak tightness, dye penetrant, inner visual inspection, go-no-go gauges,...).

CRIOTEC also contributes, in the framework of the SEA ALP Consortium, to the supply of the complete winding lines for the JT-60SA Toroidal Field Magnets, the ITER Central Solenoid Magnets and the ITER Poloidal Field (PF 2 to 5) Magnets.